Alkali Value

The molar balance between alkalis and sulphur in clinker is a crucial aspect to consider and optimize in clinker due to it's significant impacts on kiln operation and clinker quality.

HiCAl products contain high portions of sodium which allows cement manufactures with low to moderate natural alkali levels in clinker to control and increase this important chemical parameter.

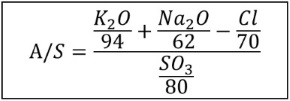

Beside the absolute contents of sulphur, potassium and sodium in percent, the molar alkali-sulphur ratio (A/S) is typically used to fully describe the situation of these important elements in clinker:

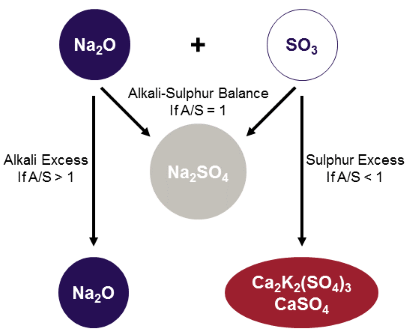

Depending whether there is a balance between alkalis and sulphur or an excess of either sulphur or alkalis, different reactions pathways with different consequences for kiln operation and clinker quality occur:

In case of alkali-sulphur balance, the most favourable situation:

Alkali and sulphur combine in clinker as alkali sulphates

Ideal for kiln process, clinker reactivity and clinker factor reduction

In case of alkali excess

Excess alkali enrich in calcium aluminate and promote formation of ortho-rhombic aluminate with potentially erratic setting behaviour

In case of sulphur excess:

Higher sulphur volatility with enhanced sulphur cycles / build-ups in kiln

Ultimately, sulphur binds to calcium and reduces alite content

Based on the above, the optimum market for HiCAl products would be clinker plants with low to moderate alkali levels and a molar sulphur excess. These plants could increase the level of alkali in clinker with HiCAl, improve their alkali-sulphur balance and profit from improved kiln operation and clinker reactivity.

Top