History

Modern technological capability built on a rich heritage

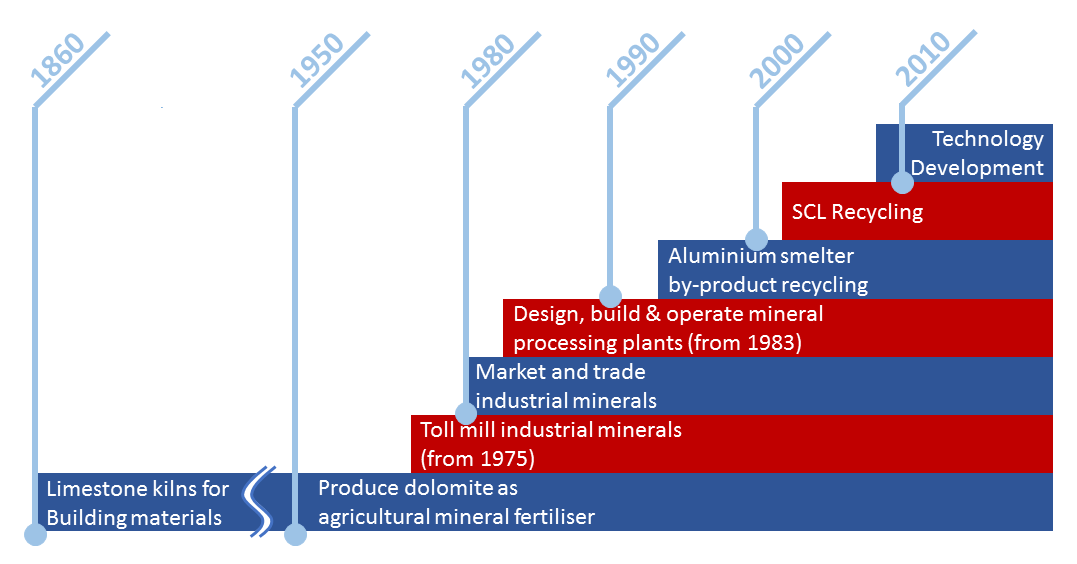

Regain is an innovative Australian mineral trading and processing company. Its beginnings date back to the mid-1800’s and the production of limestone for building use. Regain is now focussed on supporting the aluminium smelting industry.

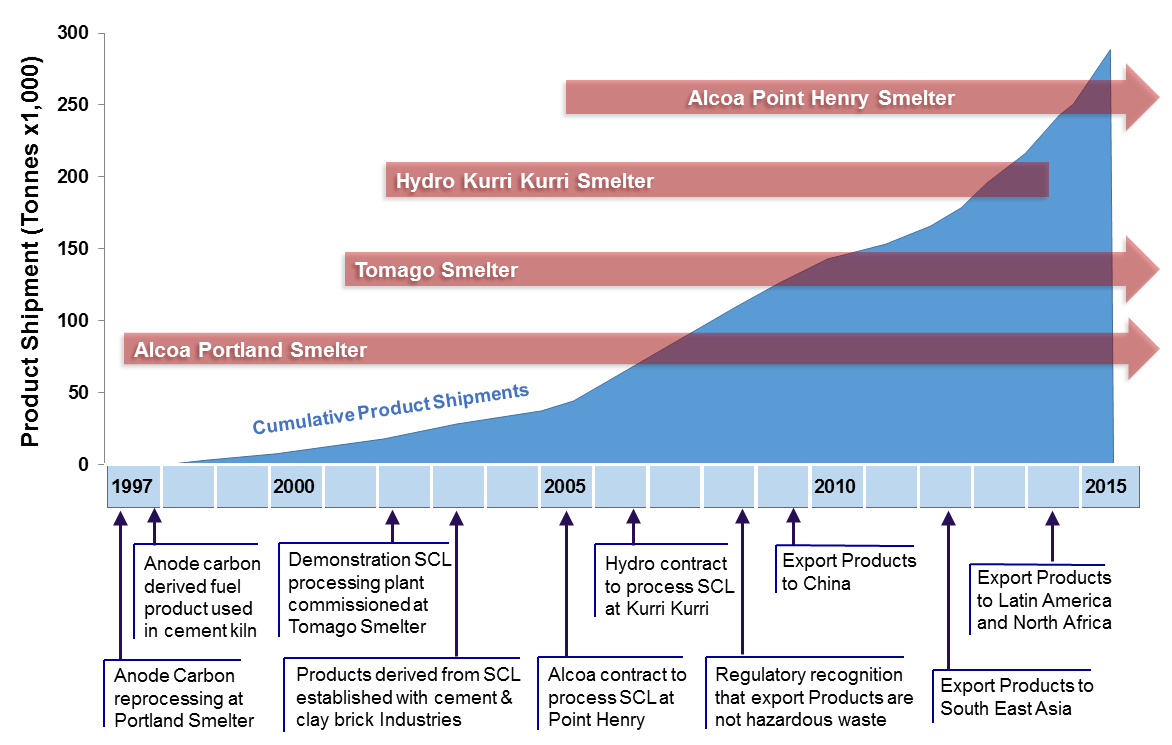

Work with the aluminium smelters began with processing refractory brick in the 1980s. Market presence, and the first long term contract to convert residual carbon material to cement kiln fuel, commenced in 1996. In 1997, the first HiCAl product (High Clinker Alite) derived from smelter waste material was used in a cement kiln at Blue Circle Southern Cement at Waurn Ponds in Victoria, Australia.

A demonstration SPL treatment plant was built and commissioned in 2002 at the Tomago smelter in the Hunter Valley, NSW, Australia. Shortly afterwards, Regain was approved by local (Victoria & NSW) regulators to manage treated smelter by-products as products, not waste. This allowed the development of a local Australian market for HiCAl products derived from SPL.

With the commissioning of the Alcoa Point Henry SPL processing facility in 2006, further opportunity arose to look into the export of HiCAl products.

An important step was made in 2008 with the advice from the Australian Government Department of Environment that Regain products were not classified as Hazardous Waste, and were therefore not subject to export regulation under the Basel Convention for the international control of hazardous waste.

With the assistance of the Australian Trade Commission (Austrade), Regain successfully exported HiCal products to China in 2009, followed by export to South East Asia and Latin America.

Meanwhile the 3rd processing plant was commissioned at Kurri Kurri in NSW.

Regain commenced exporting HiCAl products to the Philippines and Thailand in 2012. In 2014, the first shipments of HiCAl product were successfully delivered to Latin America and North Africa.

Regain continues to expand its market presence to service downstream industries that are looking for reductions in energy consumption and greenhouse gas emissions. Regain’s detailed knowledge of cement clinker processes has enabled crafting of specialised products for each customer.

The needs of the primary aluminium smelting industry have been served by flexible, individual business models that have optimised the configuration of SPL processing equipment, operating costs and product offtake.

Top